|

No |

Category |

Cutting |

Rolling |

Annotation |

|

1 |

Installation efficiency |

Low |

High |

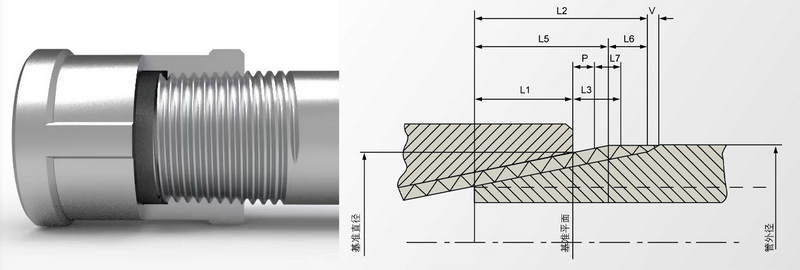

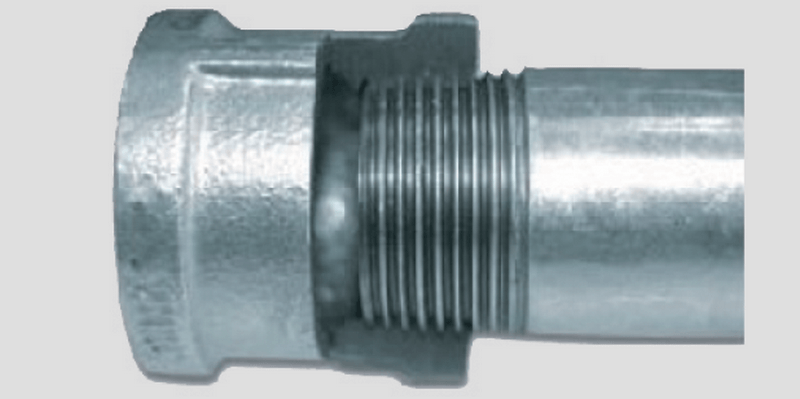

The excellent profile of the rolled pipe thread makes every tooth of taper thread perfectly matched with the female internal thread |

|

2 |

The success rate of the pressure leakage test |

Low |

Almost 100%, few with the female thread issues |

|

|

3 |

Amount of leak-proof |

100% |

50~70% less than cutting |

|

|

4 |

The thread treatment during pipe system operation |

Need, especially for the thread exposure outside after matching with the female thread parts |

Not required as Zinc coating remains |

The remaining hop-dip galvanized coating keeps the anticorrosion ability of the formed thread as same as the original pipe itself |

|

5 |

Routine maintenance |

Often |

Occasionally |

|

|

6 |

Working environment |

High tightening friction resistance and inconsistency quality of the lathe cut thread resulting in a pressure test, often call-back work needed |

The friction resistance of tightening is small, the grip of the tooth is good, the installation is easy and fast, the success rate of a pressure test is almost 100%, and an environment friendly is achieved |

No metal material cutting away, no metal scraps during thread forming, less oil, easy machine operating, less skill requirement, user-friendly |

|

7 |

Technical/Experience requirement |

Yes |

Low, It will bring tightening torque standardization |

|

|

8 |

Carbon neutrality, Energy conservation, and emission reduction |

Save 20% or more of steel used in steel pipes |

|

Schedule 40 rolled pipe nipple could play the function as well as the Schedule 80 cutting pipe Besides the pipe thickness material saving, replacing the pipe welding connection will be no issues of welding and benefits the environment |